Maximizing Efficiency: The Essential Guide to Granite Multi Blades Block Cutter Factories

Time:

Jun 09,2025

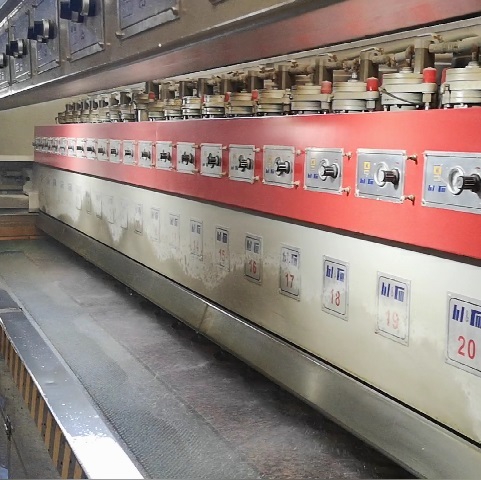

In the manufacturing and processing machinery sector, particularly in the electric tool domain, granite multi blades block cutter factories are crucial to producing high-quality stone products. These specialized factories focus on efficient cutting techniques that meet the rigorous demands of the stone industry. As a professional in this field, understanding the dynamics of these factories can significantly enhance your operational effectiveness and competitive edge.

1. **Understanding the Technology**: At the heart of granite multi blades block cutter operations lies advanced technology. Multi-blade cutters utilize multiple blades to slice through granite blocks efficiently. Familiarizing yourself with the latest innovations, such as diamond-tipped blades and computer numerical control (CNC) systems, can optimize your production process. Investing in modern machinery not only improves precision but also reduces the time taken for cutting, allowing for higher throughput.

2. **Operational Efficiency**: To maximize output, factories should focus on streamlining workflows. Implementing lean manufacturing principles can minimize waste and enhance productivity. Conducting regular maintenance on equipment ensures that machinery operates at peak performance, reducing downtime caused by repairs. Additionally, training workers on best practices in operating cutting machines fosters a culture of safety and efficiency.

3. **Quality Control**: In granite processing, quality assurance is paramount. Establishing rigorous quality control measures helps ensure that the finished products meet industry standards. This includes regular inspections of the blades and machinery, as well as the final granite blocks. By maintaining high quality, factories can build a solid reputation in the market, leading to increased demand for their products.

4. **Market Trends and Customer Needs**: Staying attuned to market trends is essential for any granite multi blades block cutter factory. Understanding customer preferences—such as the demand for specific cuts, finishes, and sizes—can guide production decisions. Additionally, keeping an eye on market prices and supply chain dynamics helps in adjusting operations to maintain profitability.

5. **Sustainability Practices**: As environmental concerns grow, integrating sustainability practices within granite multi blades block cutter factories is becoming increasingly important. This can involve recycling waste materials, using energy-efficient machinery, and sourcing raw materials responsibly. By adopting sustainable practices, factories not only comply with regulations but also appeal to environmentally conscious customers.

In conclusion, granite multi blades block cutter factories are vital to the stone cutting industry. By embracing technology, streamlining operations, ensuring quality control, responding to market trends, and promoting sustainability, professionals in this sector can significantly enhance their business performance. These strategies will not only improve efficiency but also position your factory as a leader in the competitive landscape of stone processing machinery.

1. **Understanding the Technology**: At the heart of granite multi blades block cutter operations lies advanced technology. Multi-blade cutters utilize multiple blades to slice through granite blocks efficiently. Familiarizing yourself with the latest innovations, such as diamond-tipped blades and computer numerical control (CNC) systems, can optimize your production process. Investing in modern machinery not only improves precision but also reduces the time taken for cutting, allowing for higher throughput.

2. **Operational Efficiency**: To maximize output, factories should focus on streamlining workflows. Implementing lean manufacturing principles can minimize waste and enhance productivity. Conducting regular maintenance on equipment ensures that machinery operates at peak performance, reducing downtime caused by repairs. Additionally, training workers on best practices in operating cutting machines fosters a culture of safety and efficiency.

3. **Quality Control**: In granite processing, quality assurance is paramount. Establishing rigorous quality control measures helps ensure that the finished products meet industry standards. This includes regular inspections of the blades and machinery, as well as the final granite blocks. By maintaining high quality, factories can build a solid reputation in the market, leading to increased demand for their products.

4. **Market Trends and Customer Needs**: Staying attuned to market trends is essential for any granite multi blades block cutter factory. Understanding customer preferences—such as the demand for specific cuts, finishes, and sizes—can guide production decisions. Additionally, keeping an eye on market prices and supply chain dynamics helps in adjusting operations to maintain profitability.

5. **Sustainability Practices**: As environmental concerns grow, integrating sustainability practices within granite multi blades block cutter factories is becoming increasingly important. This can involve recycling waste materials, using energy-efficient machinery, and sourcing raw materials responsibly. By adopting sustainable practices, factories not only comply with regulations but also appeal to environmentally conscious customers.

In conclusion, granite multi blades block cutter factories are vital to the stone cutting industry. By embracing technology, streamlining operations, ensuring quality control, responding to market trends, and promoting sustainability, professionals in this sector can significantly enhance their business performance. These strategies will not only improve efficiency but also position your factory as a leader in the competitive landscape of stone processing machinery.

RELATED NEWS