Maximizing Efficiency in Stone Processing: The Role of Stone Calibrating Machines

Time:

Jun 15,2025

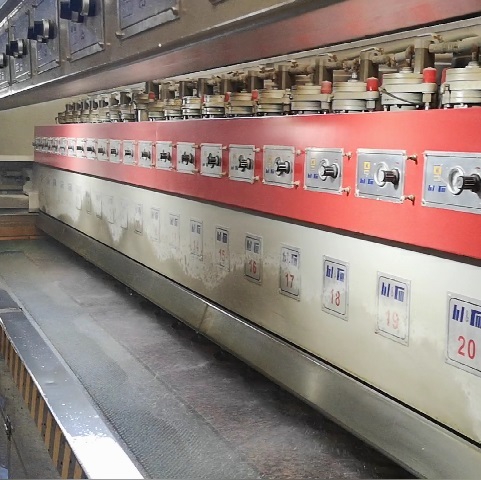

In the stone processing industry, accuracy and efficiency are paramount. Stone calibrating machines are essential tools designed to ensure that stones are processed to the correct thickness, providing a smooth and even surface during the manufacturing process. These machines help to streamline operations, reduce waste, and improve the quality of finished products, making them a vital investment for businesses involved in stone processing.

The primary function of a stone calibrating machine is to flatten and dimension stones to precise measurements. This process involves removing material from the stone’s surface while maintaining the integrity of its structure. By calibrating stones to a uniform thickness, these machines ensure compatibility with other processing equipment and facilitate easier handling during installation. Additionally, this uniformity enhances the overall aesthetic appeal of the finished product, a critical factor in the architectural and decorative materials market.

One of the key benefits of using a stone calibrating machine is improved productivity. By automating the calibration process, these machines significantly reduce the time and labor required compared to manual calibration methods. This increased efficiency allows businesses to meet higher production demands without compromising on quality. Moreover, the integration of advanced technology in modern stone calibrating machines means that operators can achieve high precision, minimizing the risk of errors that might occur with manual processes.

Another significant advantage is the reduction of material waste. Inaccurate cutting and calibration can lead to significant waste, impacting both the environment and the bottom line. Stone calibrating machines optimize material usage by ensuring that only the necessary amount of stone is removed during processing. This feature not only saves costs but also aligns with sustainable practices in the industry.

When considering the purchase of a stone calibrating machine, several factors should be taken into account. The capacity of the machine, its ease of use, and the level of maintenance required are all crucial elements that can affect its long-term efficiency. Additionally, businesses should evaluate the machine’s compatibility with their existing equipment and workflows to ensure a seamless integration into their production lines.

In conclusion, stone calibrating machines are indispensable in the stone processing industry, offering a range of benefits that enhance productivity, accuracy, and sustainability. By investing in a quality calibrating machine, businesses can improve their operational efficiency and maintain competitive advantages in the ever-evolving market of building and decorative materials. Understanding how to effectively utilize these machines will ultimately lead to better outcomes and increased customer satisfaction in your projects.

The primary function of a stone calibrating machine is to flatten and dimension stones to precise measurements. This process involves removing material from the stone’s surface while maintaining the integrity of its structure. By calibrating stones to a uniform thickness, these machines ensure compatibility with other processing equipment and facilitate easier handling during installation. Additionally, this uniformity enhances the overall aesthetic appeal of the finished product, a critical factor in the architectural and decorative materials market.

One of the key benefits of using a stone calibrating machine is improved productivity. By automating the calibration process, these machines significantly reduce the time and labor required compared to manual calibration methods. This increased efficiency allows businesses to meet higher production demands without compromising on quality. Moreover, the integration of advanced technology in modern stone calibrating machines means that operators can achieve high precision, minimizing the risk of errors that might occur with manual processes.

Another significant advantage is the reduction of material waste. Inaccurate cutting and calibration can lead to significant waste, impacting both the environment and the bottom line. Stone calibrating machines optimize material usage by ensuring that only the necessary amount of stone is removed during processing. This feature not only saves costs but also aligns with sustainable practices in the industry.

When considering the purchase of a stone calibrating machine, several factors should be taken into account. The capacity of the machine, its ease of use, and the level of maintenance required are all crucial elements that can affect its long-term efficiency. Additionally, businesses should evaluate the machine’s compatibility with their existing equipment and workflows to ensure a seamless integration into their production lines.

In conclusion, stone calibrating machines are indispensable in the stone processing industry, offering a range of benefits that enhance productivity, accuracy, and sustainability. By investing in a quality calibrating machine, businesses can improve their operational efficiency and maintain competitive advantages in the ever-evolving market of building and decorative materials. Understanding how to effectively utilize these machines will ultimately lead to better outcomes and increased customer satisfaction in your projects.

RELATED NEWS