Maximizing Efficiency with Modern Stone Cutting Machines: A Comprehensive Guide

Time:

Jun 18,2025

Maximizing Efficiency with Modern Stone Cutting Machines

Table of Contents

- 1. Introduction to Modern Stone Cutting Technology

- 2. Importance of Efficiency in Stone Cutting

- 3. Types of Modern Stone Cutting Machines

- 4. Key Features to Look for in Stone Cutting Machines

- 5. Strategies for Optimizing Efficiency

- 6. The Role of Technology in Enhancing Performance

- 7. Environmental Considerations in Stone Cutting

- 8. Future Trends in Stone Cutting Machines

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Modern Stone Cutting Technology

In today's construction and manufacturing sectors, **stone cutting machines** play a crucial role in shaping and finishing stone products. With advancements in technology, modern machines offer exceptional precision and speed, significantly enhancing operational efficiency. This article delves into the various types of stone cutting machines and their applications, while also emphasizing the importance of optimizing these tools for maximum productivity.

2. Importance of Efficiency in Stone Cutting

Efficiency in stone cutting is vital for several reasons:

1. **Cost Savings**: Reducing material waste and minimizing operational downtime leads to significant cost savings.

2. **Time Management**: Quick cutting processes allow businesses to meet tight deadlines and improve project turnaround times.

3. **Quality Enhancement**: Efficient machines produce cleaner cuts and better finishes, enhancing the overall quality of the final product.

4. **Sustainability**: Enhancing efficiency reduces energy consumption and waste, contributing to environmentally sustainable practices.

3. Types of Modern Stone Cutting Machines

Modern stone cutting machines come in various forms, each designed for specific applications and materials. Understanding these types is essential for selecting the right machine for your operations.

3.1 Diamond Wire Saw Machines

Diamond wire saw machines utilize a wire embedded with diamond segments to cut through stone with immense precision. These machines are ideal for large blocks of stone, offering faster cutting speeds and less waste compared to traditional methods. Their versatility allows for both straight and curved cuts, making them popular in the industry.

3.2 CNC Stone Cutting Machines

Computer Numerical Control (CNC) stone cutting machines provide unparalleled accuracy and automation. With programming capabilities, these machines can execute complex designs and shapes, significantly reducing manual labor. CNC machines are particularly advantageous for intricate projects requiring repetitive precision.

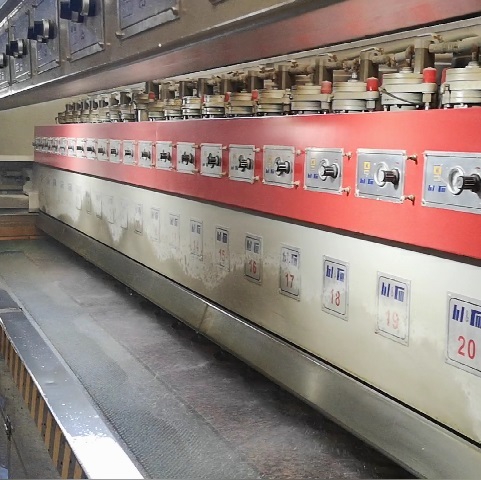

3.3 Bridge Saw Machines

Bridge saw machines are known for their stability and power. Equipped with a rotating blade, these machines cut large slabs of stone efficiently. They are ideal for straight cuts and can accommodate various stone thicknesses, making them a staple in many stone workshops.

4. Key Features to Look for in Stone Cutting Machines

When selecting stone cutting machines, consider the following features to maximize efficiency:

1. **Power and Speed**: Machines with higher horsepower and cutting speeds facilitate faster operations.

2. **Precision Controls**: Features like laser-guided cutting and programmable settings ensure accuracy.

3. **Durability**: Machines made from robust materials survive the wear and tear of daily use.

4. **Safety Features**: Look for machines with automatic shut-off mechanisms and safety guards to protect operators.

5. Strategies for Optimizing Efficiency

To fully harness the capabilities of modern stone cutting machines, businesses should implement various optimization strategies.

5.1 Regular Maintenance Practices

Routine maintenance is essential for the longevity and performance of stone cutting machines. Regularly inspect and replace worn parts, clean cutting surfaces, and ensure that the lubrication systems are functioning correctly.

5.2 Operator Training and Skill Development

Investing in training programs for operators enhances their understanding of machine capabilities and safe handling practices. Skilled operators can maximize the machine's potential, leading to improved efficiency and reduced risk of accidents.

6. The Role of Technology in Enhancing Performance

Modern stone cutting machines incorporate advanced technologies such as **IoT sensors**, **CAD/CAM software**, and **automated systems**. These technologies facilitate real-time monitoring, allowing operators to track performance metrics and make data-driven decisions. Implementing technology not only enhances efficiency but also improves overall operational management.

7. Environmental Considerations in Stone Cutting

As the industry evolves, the need for environmentally friendly practices becomes paramount. Modern stone cutting machines often come equipped with dust suppression systems and water recycling features, reducing the environmental impact of operations. Additionally, adopting sustainable materials and practices can enhance a company's reputation and appeal to eco-conscious consumers.

8. Future Trends in Stone Cutting Machines

The future of stone cutting technology is promising, with ongoing innovations aimed at improving efficiency and sustainability. Expect to see advancements such as:

1. **Automation and Robotics**: Greater integration of robotics for handling and cutting will streamline processes and reduce labor costs.

2. **Enhanced Software Solutions**: More sophisticated software for design and operational management will allow for better planning and execution.

3. **Eco-friendly Technologies**: Emerging technologies focusing on reducing energy consumption and waste will shape the future landscape of stone processing.

9. Frequently Asked Questions

1. What are the benefits of using diamond wire saw machines?

Diamond wire saw machines offer faster cutting speeds, reduced material waste, and the ability to make intricate cuts with precision.

2. How often should stone cutting machines be maintained?

Regular maintenance should occur on a scheduled basis, typically monthly or quarterly, depending on the machine's usage and workload.

3. What factors should I consider when choosing a stone cutting machine?

Consider factors such as cutting speed, precision controls, power, durability, and safety features.

4. Can CNC machines handle large stone blocks?

Yes, CNC machines can handle large stone blocks but are particularly useful for detailed and intricate designs.

5. How does technology improve stone cutting efficiency?

Technology enhances efficiency through automation, real-time monitoring, and advanced design capabilities, allowing for quicker and more accurate cuts.

10. Conclusion

Maximizing efficiency with modern stone cutting machines is vital for staying competitive in the ever-evolving stone manufacturing industry. By investing in the right equipment, implementing effective maintenance practices, and leveraging modern technologies, businesses can enhance productivity and improve the quality of their products. As we look to the future, the continuous innovation in stone cutting technology will undoubtedly pave the way for more sustainable and efficient operations.

RELATED NEWS