Methods to improve the efficiency of stone cutting

Time:

Oct 12,2024

Methods to Improve the Efficiency of Stone Cutting

Stone cutting is an essential process in various industries, including construction, sculpture, and jewelry making. However, it can be a time-consuming and labor-intensive task if not done efficiently. In this article, we will explore some methods to improve the efficiency of stone cutting, making the process faster and more cost-effective.

First and foremost, using the right tools is crucial for efficient stone cutting. Diamond blades are the most common choice for cutting stone due to their durability and precision. These blades are available in different sizes and shapes, depending on the type of stone being cut. It is essential to use a diamond blade that is specifically designed for the type of stone you are working with to ensure optimal cutting performance.

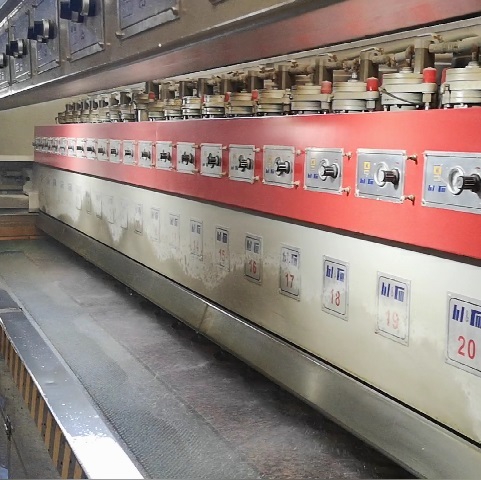

Another method to improve the efficiency of stone cutting is to invest in high-quality machinery. Stone cutting machines such as bridge saws and wire saws are designed to cut through stone quickly and accurately. These machines are equipped with advanced features such as water cooling systems to prevent overheating and dust collection systems to keep the work area clean. Investing in high-quality machinery may require a significant upfront cost, but it can greatly increase efficiency and productivity in the long run.

In addition to using the right tools and machinery, proper maintenance of equipment is essential for efficient stone cutting. Regularly inspecting and cleaning diamond blades, replacing worn-out parts, and lubricating moving components can help prevent breakdowns and ensure that the equipment operates at peak performance. Neglecting maintenance can lead to reduced cutting efficiency, increased downtime, and costly repairs.

Furthermore, optimizing cutting parameters such as blade speed, feed rate, and depth of cut can significantly improve the efficiency of stone cutting. Experimenting with different cutting parameters and adjusting them based on the type of stone and desired cut can help achieve faster cutting speeds and smoother finishes. It is essential to strike a balance between cutting speed and cutting quality to maximize efficiency without compromising the final result.

Additionally, proper training and skill development are crucial for improving the efficiency of stone cutting. Experienced operators who are familiar with the characteristics of different types of stone and know how to operate cutting equipment effectively can significantly increase productivity. Investing in training programs and workshops for employees can help improve their skills and knowledge, leading to more efficient stone cutting processes.

Lastly, embracing technology such as computer-aided design (CAD) and computer numerical control (CNC) systems can streamline the stone cutting process and enhance efficiency. CAD software allows designers to create precise cutting patterns and layouts, reducing material waste and optimizing cutting paths. CNC systems automate the cutting process, eliminating human error and ensuring consistent results. Integrating technology into stone cutting operations can increase efficiency, accuracy, and productivity.

In conclusion, improving the efficiency of stone cutting requires a combination of the right tools, machinery, maintenance practices, cutting parameters, training, and technology. By implementing these methods, businesses can increase productivity, reduce costs, and achieve better results in their stone cutting operations. Investing in efficiency improvements is essential for staying competitive in the industry and meeting the demands of customers for high-quality stone products.

RELATED NEWS