Unlocking the Potential of Granite Plate Polishing Machines for Superior Stone Finishing

Time:

Aug 21,2025

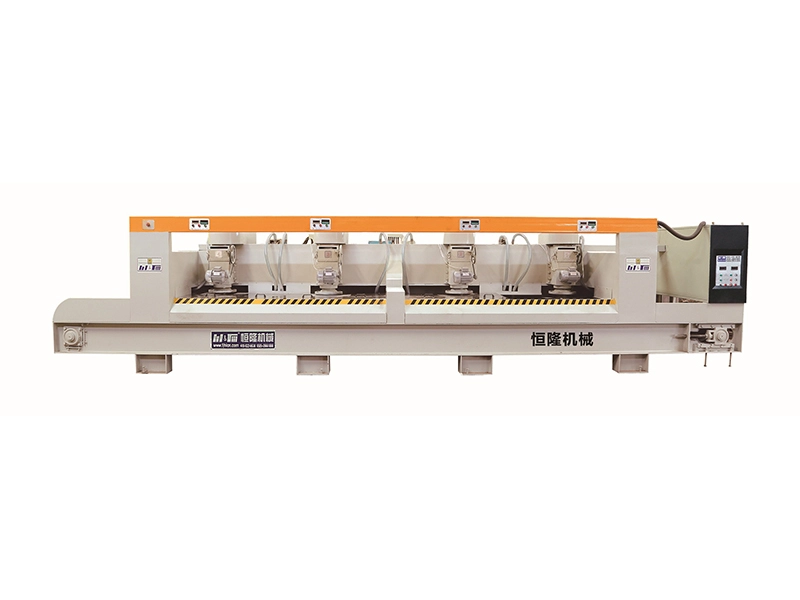

Granite plate polishing machines play a pivotal role in the stone processing industry, particularly in the finishing of granite surfaces. These machines are designed to provide a high-quality polish to granite plates, which is essential for achieving a luxurious and smooth finish. When investing in a granite plate polishing machine, it is vital to understand its features, functionality, and the overall benefits it offers.

One of the primary advantages of using a granite plate polishing machine is the efficiency it brings to the polishing process. Traditional methods of polishing can be time-consuming and labor-intensive, often yielding inconsistent results. However, with a granite plate polishing machine, operators can achieve uniformity in surface finish while significantly reducing the time required to complete the task. This efficiency not only boosts productivity but also allows for higher output, which is essential in meeting client demands.

The operation of a granite plate polishing machine is relatively straightforward, making it accessible for both seasoned professionals and newcomers to the stone processing field. These machines typically come equipped with adjustable speed settings, allowing users to customize the polishing process according to the specific type of granite and the desired finish. Many models also include features such as water recirculation systems, which help to minimize dust and debris while ensuring a smooth polishing experience.

Another critical aspect to consider is the maintenance of granite plate polishing machines. Regular maintenance is necessary to ensure optimal performance and longevity. This includes routine cleaning, inspection of polishing pads, and lubrication of moving parts. By adhering to a maintenance schedule, operators can prevent potential breakdowns and ensure that the machine operates at peak efficiency. Additionally, keeping the polishing pads in good condition is essential for achieving the best results.

When choosing a granite plate polishing machine, it is crucial to consider the specific needs of your operation. Factors such as the size of the granite plates, the desired turnaround time, and the level of finish required will influence the decision. Researching different models and understanding their capabilities can greatly aid in selecting the most suitable machine for your business.

In conclusion, granite plate polishing machines are an indispensable tool in the stone processing industry, offering efficiency, reliability, and high-quality results. By understanding the operational aspects and maintenance requirements of these machines, businesses can enhance their granite finishing processes, leading to improved customer satisfaction and increased profitability. Investing in the right granite plate polishing machine is a step toward achieving excellence in stone craftsmanship.

RELATED NEWS