Common Myths About Multi Blades Stone Block Cutting Debunked: Understanding the Truth Behind the Techniques

Time:

Aug 26,2025

Common Myths About Multi Blades Stone Block Cutting Debunked

Introduction to Multi Blades Stone Block Cutting

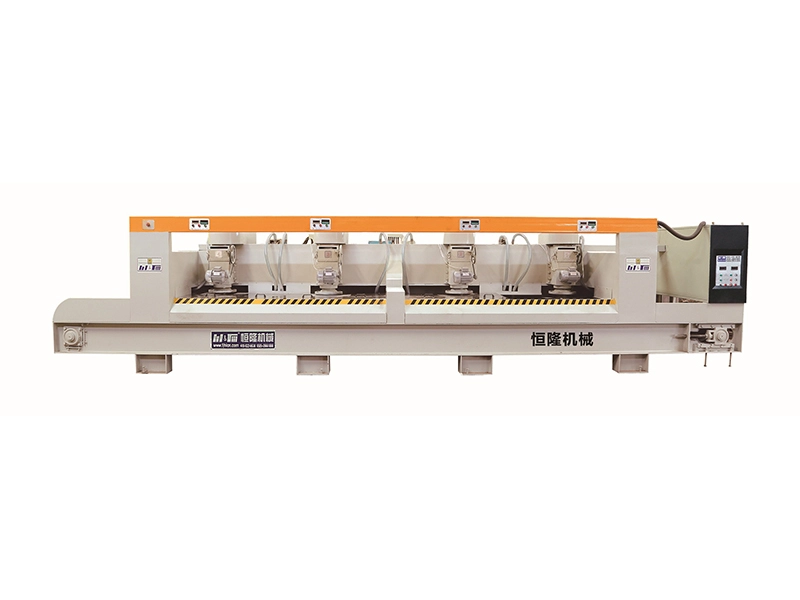

The process of cutting stone blocks is critical in the construction and decoration industry. With the advent of modern technology, **multi blades stone cutting machines** have become a popular choice due to their efficiency and precision. However, various myths and misconceptions surround this technique, leading to confusion among professionals and enthusiasts alike. In this article, we will debunk common myths about multi blades stone block cutting, providing you with factual insights to improve your understanding and application of this technology.

Table of Contents

- Myth 1: Multi Blades Are Only for Large Projects

- Myth 2: Multi Blades Are Less Accurate

- Myth 3: All Blades Are Created Equal

- Myth 4: Only Experienced Operators Can Use Multi Blades

- Myth 5: Multi Blade Cutting Machines Are Too Expensive

- Myth 6: Maintenance Is Complicated and Time-Consuming

- Myth 7: Stone Block Cutting Is a Simple Process

- Myth 8: The Quality of Cut Doesn’t Matter

- FAQs About Multi Blades Stone Block Cutting

- Conclusion

Myth 1: Multi Blades Are Only for Large Projects

A common misconception is that multi blades are exclusively designed for large-scale projects. While it is true that these machines excel in high-volume cutting operations, they are not limited to grand constructions. In fact, **multi blade cutting technology** can significantly enhance efficiency even in smaller projects. This versatility allows contractors to save time and reduce waste, making it an excellent investment for businesses of all sizes.

Myth 2: Multi Blades Are Less Accurate

Another prevalent myth is that multi blades compromise accuracy in stone cutting. In reality, multi blade machines are engineered to provide high precision. With advanced alignment technologies and computerized controls, these machines ensure consistent cuts with minimal deviation. The key to achieving accurate results lies in proper setup and calibration, not the cutting method itself.

Myth 3: All Blades Are Created Equal

The assumption that all blades used in multi-blade cutting machines are the same is misleading. Different applications require specific blade types designed for various stone materials. For example, diamond blades are ideal for hard stone, while carbide blades work better for softer materials. Understanding the differences and choosing the right blade is crucial for optimal cutting performance and longevity.

Myth 4: Only Experienced Operators Can Use Multi Blades

It is often believed that only seasoned professionals can operate multi blades effectively. While experience certainly helps, these machines are designed with user-friendly interfaces and safety features that make them accessible to operators of varying skill levels. Comprehensive training programs are available, ensuring that even novice users can handle these machines competently.

Myth 5: Multi Blade Cutting Machines Are Too Expensive

The perception that multi blade cutting machines are prohibitively expensive can deter businesses from investing in them. While the initial investment may seem significant, the long-term benefits outweigh the costs. These machines offer increased efficiency, reduced labor costs, and improved output quality. Additionally, many financing options exist to make the acquisition more feasible for smaller businesses.

Myth 6: Maintenance Is Complicated and Time-Consuming

Many believe that maintaining multi blade cutting machines is a daunting task. On the contrary, regular maintenance is straightforward and can be performed with minimal downtime. Following the manufacturer’s guidelines and conducting routine checks will ensure the machine operates efficiently. Simple tasks such as cleaning and lubricating components can significantly extend the lifespan of the equipment.

Myth 7: Stone Block Cutting Is a Simple Process

Some people underestimate the complexity of stone block cutting, assuming it is merely a matter of running a machine. In reality, successful cutting requires an understanding of various factors, including the type of stone, blade selection, and cutting techniques. Inadequate knowledge can lead to poor results and waste. Proper training and experience are essential for achieving quality cuts.

Myth 8: The Quality of Cut Doesn’t Matter

Lastly, the notion that the quality of the cut is unimportant is fundamentally flawed. In the construction and decoration industry, the quality of stone cut can significantly impact the overall aesthetic and structural integrity of a project. Poorly cut stones can lead to gaps, misalignments, and additional costs for rectification. Investing in high-quality cutting techniques and equipment pays off in the long run.

FAQs About Multi Blades Stone Block Cutting

1. What types of stones can be cut using multi blade machines?

Multi blade machines can cut various types of stones, including granite, marble, limestone, and sandstone. The choice of blade is crucial for ensuring optimal performance across different stone materials.

2. How do I know which blade to use for my project?

Selecting the right blade depends on the stone type and the desired finish. Consulting with blade manufacturers or experienced operators can provide valuable insights into the best blade options for specific applications.

3. What safety precautions should be taken when operating multi blade machines?

Operators should wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and ear protection. Additionally, ensuring that the machine is properly maintained and following operational guidelines can minimize risks.

4. Can multi blade cutting machines be used for decorative stone cutting?

Yes, multi blade cutting machines can be effectively used for decorative stone cutting. When equipped with the right blades, these machines allow for intricate designs and precise detailing, making them suitable for various ornamental applications.

5. What is the typical lifespan of a blade used in multi blade cutting?

The lifespan of a blade varies based on factors such as the type of stone, cutting speed, and frequency of use. Generally, a well-maintained blade can last for several hours of cutting, but regular inspections and replacements are essential for maintaining quality.

Conclusion

Debunking these common myths about multi blades stone block cutting reveals the true potential and efficiency of this technology. Understanding the facts behind these misconceptions enables professionals in the construction and decoration industry to make informed decisions regarding equipment and techniques. By investing in proper training, selecting the right blades, and maintaining machines adequately, businesses can enhance their productivity and output quality. Ultimately, embracing the realities of multi blade cutting technology paves the way for more successful and efficient stone processing.

RELATED NEWS