Why Multi Blades Stone Cutting Machines are a Must-Have for Contractors

Time:

Sep 05,2025

Why Multi Blades Stone Cutting Machines are a Must-Have for Contractors

Table of Contents

- 1. Introduction to Multi Blades Stone Cutting Machines

- 2. Key Benefits of Multi Blades Stone Cutting Machines

- 2.1 Increased Efficiency

- 2.2 Unmatched Precision

- 2.3 Cost-Effectiveness

- 2.4 Enhanced Safety Features

- 3. The Technology Behind Multi Blades Stone Cutting Machines

- 4. Practical Applications in Construction and Decoration

- 5. How to Choose the Right Multi Blades Stone Cutting Machine

- 6. Maintenance Tips for Longevity

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Multi Blades Stone Cutting Machines

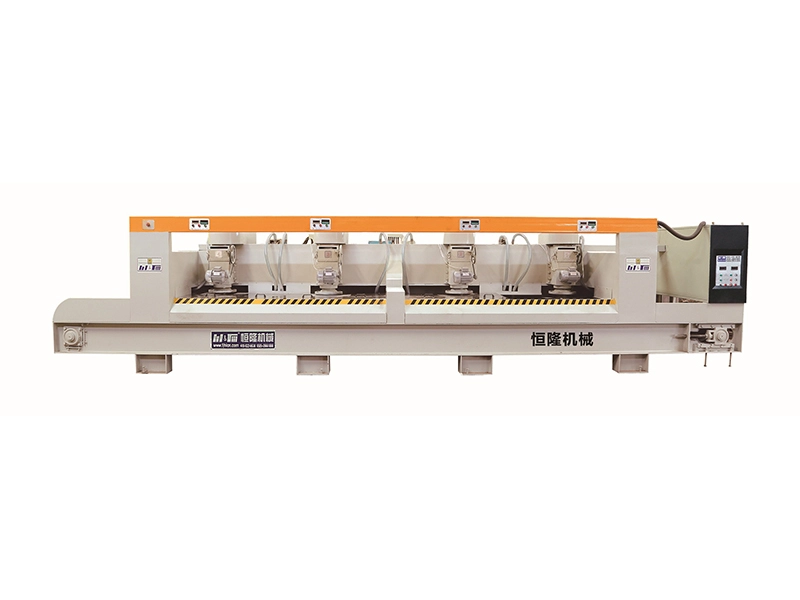

In the ever-evolving landscape of the construction and stone processing industry, **multi blades stone cutting machines** stand out as essential tools for contractors. These machines are designed to streamline the cutting process of various stone materials, offering unparalleled advantages that cater to the needs of modern contractors. By using this technology, professionals can significantly improve their workflow, meet tight deadlines, and ultimately enhance the quality of their work.

2. Key Benefits of Multi Blades Stone Cutting Machines

2.1 Increased Efficiency

One of the most prominent advantages of using **multi blades stone cutting machines** is the remarkable efficiency they bring to any project. Traditional cutting methods typically involve the use of single-blade saws, which can be time-consuming and labor-intensive. In contrast, multi blades machines can cut through multiple slabs at once, dramatically reducing the time needed to complete large jobs. This efficiency not only boosts productivity but also allows contractors to take on more projects without compromising quality.

2.2 Unmatched Precision

Precision is crucial in any stone-cutting operation, especially when dealing with intricate designs or high-end finishes. **Multi blades stone cutting machines** are engineered to deliver exceptional accuracy, minimizing the likelihood of errors that can lead to costly rework. With advanced laser-guided systems and automated features, these machines ensure that every cut is uniform and meets the exact specifications required for the project.

2.3 Cost-Effectiveness

Investing in **multi blades stone cutting machines** can yield significant long-term savings. While the initial investment may seem substantial, the efficiency and speed of these machines reduce labor costs and minimize wasted materials. Additionally, by producing higher-quality cuts, contractors can often command better pricing for their services, enhancing overall profitability.

2.4 Enhanced Safety Features

Safety is a top priority in any construction environment. Modern **multi blades stone cutting machines** are equipped with advanced safety features aimed at protecting operators and reducing the risk of accidents. Features such as emergency shutdown systems, safety guards, and dust collection mechanisms not only improve the safety of the work environment but also enhance the overall quality of the cutting process.

3. The Technology Behind Multi Blades Stone Cutting Machines

Understanding the technology that powers **multi blades stone cutting machines** can help contractors appreciate their value even more.

3.1 Types of Blades Used

The effectiveness of a stone cutting machine largely depends on the type of blades it utilizes. Typically, these machines employ diamond blades, known for their durability and strength. **Diamond blades** can cut through a variety of stone types, including granite, marble, and limestone, making them versatile tools for contractors.

3.2 Cutting Methods Explained

**Multi blades stone cutting machines** generally operate using different cutting methods such as dry cutting and wet cutting. Dry cutting is ideal for quick jobs and requires less setup, while wet cutting is preferred for its ability to minimize dust and heat, providing a cleaner and safer environment. Understanding these methods allows contractors to choose the appropriate approach for each project.

4. Practical Applications in Construction and Decoration

The applications of **multi blades stone cutting machines** span various sectors, from residential construction to commercial decoration. These machines are instrumental in creating countertops, tiles, and intricate stone features, allowing contractors to meet diverse client demands. Their ability to handle large volumes of material efficiently makes them a go-to solution for contractors engaged in high-demand environments.

5. How to Choose the Right Multi Blades Stone Cutting Machine

Selecting the right machine is crucial for maximizing efficiency and effectiveness in stone cutting.

5.1 Considerations of Size and Capacity

When choosing a **multi blades stone cutting machine**, it’s essential to consider the size and capacity that will best meet your operational needs. Larger machines can accommodate bigger slabs and higher volumes, while smaller machines may be better suited for specialized or intricate work. Assessing the typical size of the materials you work with will guide your decision.

5.2 Selecting Reliable Brands

Not all machines are created equal. Opting for reputable brands known for their durability, performance, and support can make a significant difference in the long run. Reading reviews and seeking recommendations from industry peers can provide insights into which brands offer the best value for your investment.

6. Maintenance Tips for Longevity

To ensure the longevity and optimal performance of your **multi blades stone cutting machine**, regular maintenance is essential. Here are some tips to keep your machine in top shape:

- **Regular Inspections**: Frequently check the condition of blades and other components to identify wear and prevent issues before they escalate.

- **Proper Cleaning**: Maintain a clean work environment by regularly cleaning dust and debris from the machine.

- **Lubrication**: Ensure that all moving parts are adequately lubricated to reduce friction and wear.

- **Follow Manufacturer Guidelines**: Adhere to all maintenance recommendations provided by the manufacturer for best practices.

7. Frequently Asked Questions

What types of stone can be cut using a multi blades stone cutting machine?

Multi blades stone cutting machines can effectively cut various types of stone, including granite, marble, quartz, and limestone.

Are multi blades stone cutting machines suitable for small projects?

While these machines are designed for efficiency in larger projects, they can also be adapted for smaller tasks by adjusting cutting methods and settings.

How do I maintain the blades of my stone cutting machine?

Regularly inspect blades for wear, clean them after use, and replace them as needed to ensure consistent performance.

What safety precautions should I take while operating a multi blades stone cutting machine?

Always wear appropriate personal protective equipment, ensure that safety guards are in place, and familiarize yourself with the machine's emergency shutoff features.

Can I use a multi blades stone cutting machine for decorative stone work?

Yes, these machines are excellent for both functional and decorative stone work, allowing for detailed cuts and designs.

8. Conclusion

**Multi blades stone cutting machines** are invaluable assets for contractors in the construction and stone processing industries. Their efficiency, precision, and safety features make them essential tools that can elevate the quality of work while reducing operational costs. By investing in the right machine and adhering to maintenance best practices, contractors can enhance their productivity and deliver superior results. Embracing this technology is not just a choice; it’s a necessity for those looking to succeed in a competitive market.

RELATED NEWS