Enhancing Stone Surfaces: The Role of Granite Plate Polishing Machines in the Stone Processing Industry

Time:

Aug 11,2025

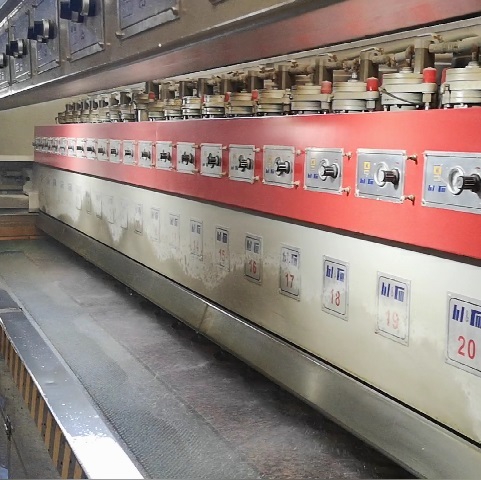

Granite plate polishing machines are essential tools in the building and decorative materials industry, especially in the stone processing segment. These machines are specifically designed to achieve a smooth, high-gloss finish on granite surfaces, which is vital for both aesthetic appeal and functional use. Understanding how these machines operate and the benefits they provide can significantly enhance the efficiency and quality of stone processing operations.

The primary role of a granite plate polishing machine is to utilize various polishing techniques to refine the surface of granite slabs or plates. Typically, these machines employ a combination of rotary movement and abrasive pads to achieve the desired finish. The abrasives used can vary in grit size, allowing for a gradual smoothing process that removes imperfections and brings out the natural beauty of the stone. By using a granite plate polishing machine, operators can ensure consistent results across multiple pieces, which is crucial for large-scale projects.

One of the key benefits of utilizing these machines is the time efficiency they offer. Manual polishing is a labor-intensive process that can be time-consuming. In contrast, a granite plate polishing machine can significantly reduce the time required to achieve a high-quality finish. This efficiency not only streamlines the production process but also reduces labor costs in the long run.

Moreover, modern granite plate polishing machines are often equipped with advanced technology that allows for greater precision and control. Features such as programmable settings and automated functions enable operators to achieve uniform results with minimal effort. This level of control is particularly beneficial when working with intricate designs or varying stone thicknesses, ensuring that each piece meets the required specifications.

Another important aspect to consider is the environmental impact of stone processing. Many granite plate polishing machines are designed with sustainability in mind. They are capable of recycling water used in the polishing process, reducing waste and conserving natural resources. Additionally, advancements in technology have led to the development of more energy-efficient machines, contributing to a lower carbon footprint for stone processing operations.

In conclusion, granite plate polishing machines play a pivotal role in enhancing the quality of stone products within the building and decorative materials industry. By understanding their functionality and benefits, professionals in the stone processing sector can make informed decisions that improve efficiency, reduce costs, and promote sustainability. Investing in these machines not only elevates the standard of finished products but also positions businesses to meet the growing demands of the market with confidence.

The primary role of a granite plate polishing machine is to utilize various polishing techniques to refine the surface of granite slabs or plates. Typically, these machines employ a combination of rotary movement and abrasive pads to achieve the desired finish. The abrasives used can vary in grit size, allowing for a gradual smoothing process that removes imperfections and brings out the natural beauty of the stone. By using a granite plate polishing machine, operators can ensure consistent results across multiple pieces, which is crucial for large-scale projects.

One of the key benefits of utilizing these machines is the time efficiency they offer. Manual polishing is a labor-intensive process that can be time-consuming. In contrast, a granite plate polishing machine can significantly reduce the time required to achieve a high-quality finish. This efficiency not only streamlines the production process but also reduces labor costs in the long run.

Moreover, modern granite plate polishing machines are often equipped with advanced technology that allows for greater precision and control. Features such as programmable settings and automated functions enable operators to achieve uniform results with minimal effort. This level of control is particularly beneficial when working with intricate designs or varying stone thicknesses, ensuring that each piece meets the required specifications.

Another important aspect to consider is the environmental impact of stone processing. Many granite plate polishing machines are designed with sustainability in mind. They are capable of recycling water used in the polishing process, reducing waste and conserving natural resources. Additionally, advancements in technology have led to the development of more energy-efficient machines, contributing to a lower carbon footprint for stone processing operations.

In conclusion, granite plate polishing machines play a pivotal role in enhancing the quality of stone products within the building and decorative materials industry. By understanding their functionality and benefits, professionals in the stone processing sector can make informed decisions that improve efficiency, reduce costs, and promote sustainability. Investing in these machines not only elevates the standard of finished products but also positions businesses to meet the growing demands of the market with confidence.