Mastering the Art of Marble Plate Polishing: Essential Insights for Professionals

Time:

Sep 30,2025

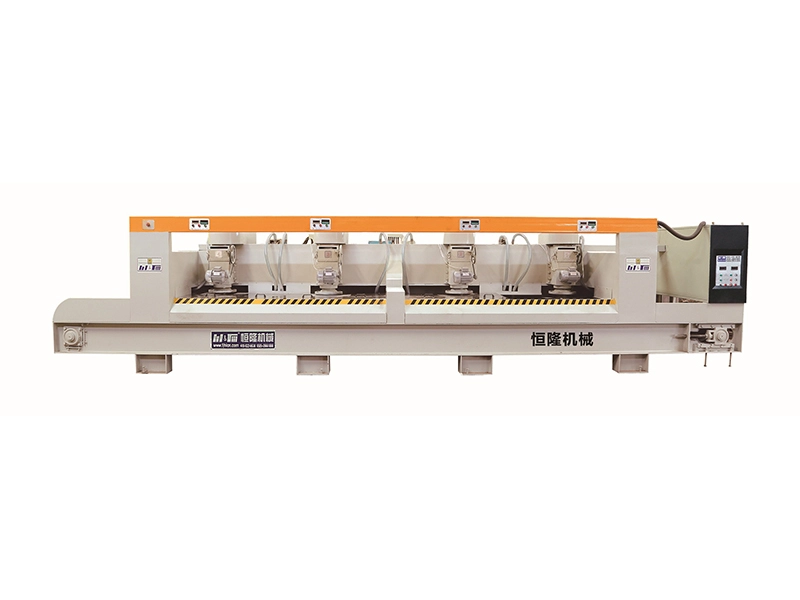

Marble plate polishing is a specialized process that enhances the aesthetic and functional qualities of marble surfaces, commonly used in various applications, from countertops to decorative elements in architecture. Professionals in the electric tool manufacturing industry often utilize marble plate polishers to achieve the desired shine and smoothness on these surfaces. Understanding the intricacies of this process can significantly benefit those working with marble in any capacity.

The primary function of a marble plate polisher is to refine the surface of the marble, removing scratches, stains, and imperfections. This is typically achieved through a series of grinding and polishing steps, which involve progressively finer grit pads. Beginning with coarser grits helps to eliminate deeper scratches, while finer grits gradually enhance the luster. The final stages of polishing often involve the use of specialized compounds that can impart a high-gloss finish.

When selecting a marble plate polisher, it is important to consider the machine's power and speed settings, as these can greatly affect the outcome of the polishing process. A variable speed option is particularly advantageous, allowing professionals to adjust the tool's performance based on the specific needs of the marble being polished. Additionally, ensuring that the machine is compatible with various polishing pads and compounds is essential for versatility in different projects.

Another critical aspect of using a marble plate polisher is the technique employed during the polishing process. Professionals should ensure that the polisher is held at the correct angle to avoid uneven wear on the marble surface. Additionally, consistent, overlapping motions should be used to ensure that all areas are evenly polished. This requires a delicate balance of pressure and speed, as excessive force can lead to damage, while insufficient pressure may not yield the desired results.

Safety precautions are also paramount when using electric polishing machines. Professionals should always wear appropriate personal protective equipment, such as goggles and dust masks, to mitigate risks associated with dust inhalation and flying debris. Proper ventilation in the workspace is also advisable to maintain air quality during the polishing process.

In conclusion, mastering the use of a marble plate polisher is vital for professionals involved in the manufacturing and processing of marble products. By understanding the operation, techniques, and safety measures of these powerful tools, individuals can elevate their craftsmanship, resulting in beautifully polished marble surfaces that are both visually appealing and durable. Whether you're a seasoned professional or new to the field, honing your skills in marble plate polishing can lead to exceptional outcomes in your projects.

The primary function of a marble plate polisher is to refine the surface of the marble, removing scratches, stains, and imperfections. This is typically achieved through a series of grinding and polishing steps, which involve progressively finer grit pads. Beginning with coarser grits helps to eliminate deeper scratches, while finer grits gradually enhance the luster. The final stages of polishing often involve the use of specialized compounds that can impart a high-gloss finish.

When selecting a marble plate polisher, it is important to consider the machine's power and speed settings, as these can greatly affect the outcome of the polishing process. A variable speed option is particularly advantageous, allowing professionals to adjust the tool's performance based on the specific needs of the marble being polished. Additionally, ensuring that the machine is compatible with various polishing pads and compounds is essential for versatility in different projects.

Another critical aspect of using a marble plate polisher is the technique employed during the polishing process. Professionals should ensure that the polisher is held at the correct angle to avoid uneven wear on the marble surface. Additionally, consistent, overlapping motions should be used to ensure that all areas are evenly polished. This requires a delicate balance of pressure and speed, as excessive force can lead to damage, while insufficient pressure may not yield the desired results.

Safety precautions are also paramount when using electric polishing machines. Professionals should always wear appropriate personal protective equipment, such as goggles and dust masks, to mitigate risks associated with dust inhalation and flying debris. Proper ventilation in the workspace is also advisable to maintain air quality during the polishing process.

In conclusion, mastering the use of a marble plate polisher is vital for professionals involved in the manufacturing and processing of marble products. By understanding the operation, techniques, and safety measures of these powerful tools, individuals can elevate their craftsmanship, resulting in beautifully polished marble surfaces that are both visually appealing and durable. Whether you're a seasoned professional or new to the field, honing your skills in marble plate polishing can lead to exceptional outcomes in your projects.

RELATED NEWS