Marble Granite Line Polisher Overview

Time:

Aug 06,2025

The Marble Granite Line Polisher is a high-efficiency, automated surface finishing machine specifically designed for continuous polishing of marble and granite slabs. It plays a critical role in stone processing plants, enabling the smooth, glossy, and uniform finish necessary for residential, commercial, and architectural stone applications.

Working Principle and Design

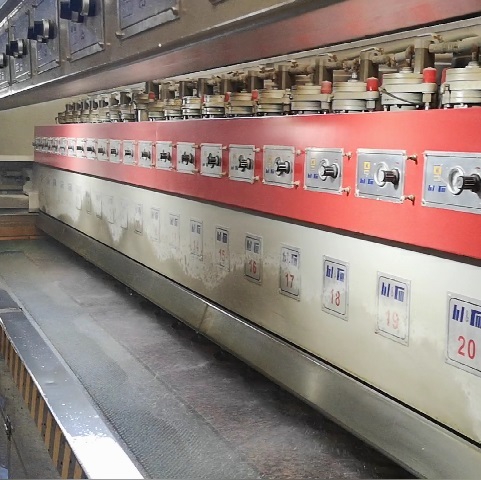

The machine typically consists of a conveyor system that moves stone slabs continuously under a series of polishing heads. These heads are equipped with abrasive pads or diamond tools that rotate at high speeds and apply variable pressure depending on the type of stone and desired finish. The polishing heads are arranged linearly, allowing each slab to pass through multiple stages of grinding, smoothing, and shining in a single run.

Key Features

High Throughput:

Line polishers can process multiple slabs per hour, making them ideal for large-scale operations.

Automated Control Systems:

Equipped with PLC or touchscreen control panels, operators can set and monitor speed, pressure, water flow, and polishing cycles.

Adjustable Head Pressure:

Each polishing head can adapt pressure individually for uneven surfaces, ensuring a uniform finish across the slab.

Water Cooling and Dust Management:

Integrated water nozzles reduce heat from friction and prevent dust, protecting both the stone and the machinery.

Durable Frame:

The machine is typically constructed from corrosion-resistant, heavy-duty steel for longevity and stability.

Applications

Flooring and Wall Cladding Panels:

The polished slabs are often used in interior and exterior flooring or wall coverings.

Kitchen Countertops & Bathroom Vanities:

A fine polished finish enhances the appearance and hygiene of kitchen and bathroom surfaces.

Architectural Projects:

High-end buildings and monuments require consistent, high-gloss finishes provided by line polishers.

Tombstones and Memorials:

The smooth, reflective surfaces are essential for engraving and aesthetics.

Benefits

Consistency:

Automated polishing ensures every slab has the same quality and finish, reducing manual errors.

Efficiency:

Multiple polishing heads and conveyor systems speed up production dramatically compared to hand or semi-automatic polishing.

Labor Saving:

Requires minimal manual intervention, significantly lowering labor costs and increasing productivity.

Cost-Effective Over Time:

Though the initial investment is substantial, the long-term benefits in speed, quality, and output justify the cost.

Versatility:

Can handle a wide range of stone types, thicknesses, and hardness levels.

Conclusion

The Marble Granite Line Polisher is indispensable in modern stone fabrication lines. With its automation, high speed, and precision, it helps manufacturers meet global demand for polished natural stone products with uniform quality and outstanding visual appeal.