Transform Your Stone Finishes with a Granite Plate Polishing Machine

Time:

Aug 06,2025

Transform Your Stone Finishes with a Granite Plate Polishing Machine

Table of Contents

- 1. Introduction to Granite Plate Polishing Machines

- 2. Benefits of Using a Granite Plate Polishing Machine

- 3. How Does a Granite Plate Polishing Machine Work?

- 4. Applications of Granite Plate Polishing Machines

- 5. Choosing the Right Granite Plate Polishing Machine

- 6. Maintenance Tips for Granite Plate Polishing Machines

- 7. Safety Measures When Using Polishing Machines

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Granite Plate Polishing Machines

In the world of stone processing and finishing, **granite plate polishing machines** play a pivotal role in enhancing the aesthetic appeal and durability of granite surfaces. These machines are specifically designed to achieve a high-quality finish that not only showcases the natural beauty of stone but also prolongs its lifespan. This article will delve into the mechanics, advantages, and applications of granite plate polishing machines, providing you with the knowledge to transform your stone finishes effectively.

2. Benefits of Using a Granite Plate Polishing Machine

The use of a granite plate polishing machine offers a myriad of benefits, making it an essential tool in the stone finishing industry. Here are some of the key advantages:

2.1 Superior Finish Quality

A granite plate polishing machine is engineered to deliver a **consistent, high-gloss finish** that manual polishing methods simply cannot match. The precision of these machines allows for an even surface texture, free of imperfections.

2.2 Increased Efficiency

In comparison to traditional methods, granite plate polishing machines significantly reduce the time required for polishing. This efficiency is critical for businesses aiming to meet tight deadlines while maintaining quality.

2.3 Cost-Effective Solutions

While the initial investment in a granite plate polishing machine may seem significant, the long-term savings on labor costs and increased productivity make it a cost-effective choice. Additionally, high-quality finishes can lead to higher selling prices.

2.4 Versatility in Applications

Granite plate polishing machines are versatile, capable of handling various types of stone materials beyond granite, including marble and quartz. This adaptability makes them valuable assets for stone processing companies.

3. How Does a Granite Plate Polishing Machine Work?

Understanding the mechanics behind granite plate polishing machines can help you appreciate their efficiency and precision. These machines utilize a combination of rotating pads, water, and polishing compounds to achieve the desired finish.

3.1 Components of the Machine

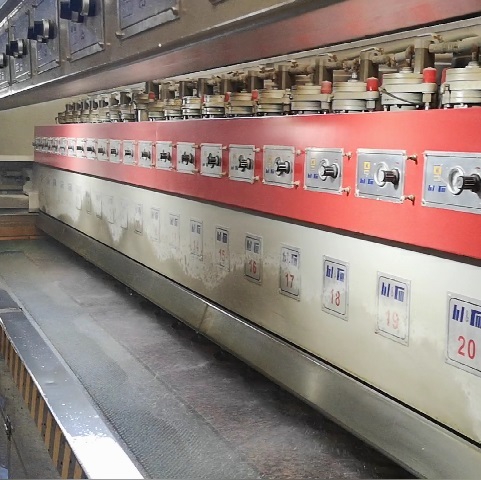

A typical granite plate polishing machine comprises the following essential components:

- **Rotating Polishing Pads**: These pads are responsible for the actual polishing action. They can vary in grit size, allowing for a range of finishes from coarse grinding to fine polishing.

- **Water Supply System**: Water is used to cool the stone and the pads during polishing, preventing overheating and dust generation, which can compromise the quality of the finish.

- **Control Panel**: Modern machines come equipped with user-friendly control panels that allow operators to adjust speed, pressure, and other parameters for optimal results.

3.2 The Polishing Process

The polishing process typically involves several stages:

1. **Initial Grinding**: Coarse pads are used to remove any surface irregularities.

2. **Intermediate Polishing**: Finer pads are employed to refine the surface texture.

3. **Final Polishing**: The finest pads are used to achieve a high-gloss finish.

Each stage is crucial in ensuring that the final product meets the highest standards of quality.

4. Applications of Granite Plate Polishing Machines

Granite plate polishing machines are widely used across various sectors, showcasing their effectiveness and versatility.

4.1 Construction Industry

In the construction industry, these machines are vital for finishing granite countertops, tiles, and flooring. A polished granite surface not only enhances aesthetics but also provides durability against wear and tear.

4.2 Monument and Memorial Production

Granite polishing machines are essential for creating beautifully polished memorials and monuments. The ability to achieve high gloss allows for intricate designs and engravings to stand out.

4.3 Interior Design and Architecture

In interior design, polished granite is a favored choice for decorative elements, accent walls, and flooring. The versatility of granite plate polishing machines enables designers to create stunning, customized features.

5. Choosing the Right Granite Plate Polishing Machine

Selecting the right granite plate polishing machine is crucial for maximizing productivity and achieving quality finishes. Consider the following factors:

5.1 Machine Size and Capacity

Evaluate the volume of work you anticipate. Larger machines may handle bigger slabs, while compact models are suitable for smaller applications.

5.2 Power and Performance

Look for machines with adequate power ratings to ensure efficient polishing, especially for dense stone materials.

5.3 Features and Technology

Modern machines come with advanced features such as digital controls, automatic speed adjustments, and programmable settings. These features can enhance usability and performance.

5.4 Cost vs. Value

Compare various models to find a balance between cost and functionality, ensuring that you invest in a machine that offers the best value for your specific needs.

6. Maintenance Tips for Granite Plate Polishing Machines

Proper maintenance of your granite plate polishing machine is essential for ensuring longevity and optimal performance. Here are some key maintenance tips:

6.1 Regular Cleaning

Keep the machine clean by removing dust and debris after each use. This practice prevents contamination that could affect the polishing quality.

6.2 Inspecting Components

Regularly inspect polishing pads for wear and tear. Replace them as necessary to maintain consistent polishing results.

6.3 Lubrication

Ensure that all moving parts are adequately lubricated to prevent friction and mechanical failure.

6.4 Follow Manufacturer Guidelines

Adhere to the manufacturer’s recommendations for maintenance schedules and procedures to ensure the machine operates effectively.

7. Safety Measures When Using Polishing Machines

Safety should always be a priority when operating granite plate polishing machines. Implement the following safety measures:

7.1 Personal Protective Equipment (PPE)

Always wear appropriate PPE, including safety goggles, gloves, and ear protection, to safeguard against potential hazards.

7.2 Training and Awareness

Ensure that all operators are adequately trained in the use of the machine. Familiarize them with safety protocols and emergency procedures.

7.3 Work Environment

Maintain a clean and organized work environment to minimize risks associated with slips, trips, and falls.

8. Frequently Asked Questions (FAQs)

8.1 What types of stones can be polished with a granite plate polishing machine?

Granite plate polishing machines can effectively polish various types of stones, including granite, marble, and quartz.

8.2 How often should I replace polishing pads?

The frequency of pad replacement depends on usage. Inspect pads regularly and replace them when they show signs of wear.

8.3 Can granite plate polishing machines be used for rough surfaces?

Yes, these machines can be utilized for rough surfaces, starting with coarse pads to achieve a smooth finish.

8.4 What is the average cost of a granite plate polishing machine?

The cost varies widely based on features and brand, ranging from a few thousand dollars to over ten thousand dollars.

8.5 Are there any specific maintenance requirements for these machines?

Regular cleaning, lubrication, and inspection of components are crucial for maintaining the machine's performance and longevity.

9. Conclusion

In summary, granite plate polishing machines are invaluable tools in the stone finishing industry, offering superior quality, efficiency, and versatility. By understanding their benefits, applications, and maintenance needs, you can make informed decisions that enhance your stone processing capabilities. Investing in a granite plate polishing machine will undoubtedly transform your stone finishes, unlocking the potential for increased productivity and profit in your business. Embrace the future of stone finishing by integrating technology that elevates your work to the next level.